Who We Are

DENP Industrial is a global manufacturer and supplier of crusher wear parts, crusher spare parts and original Shanbao brand stone crushers. DENP Foundry takes up 15000 square meter’s factory, and produce capacity of around 9000 tons annually,84 workers and 7 engineers. The biggest single casting we can make is 6 tons and diameter no more than 3 meters. DENP’s products have a 20% to 30% longer service life than other traditional manganese and Chrome products in China. We has established import and export business since 2010 and have many years of history in the casting steel industry, basis on a foothold in the domestic market to a large number of exports to the overseas market.

DENP foundry founded in 1997, corrosion resistance, wear resistance, impact-resistant product development, and production. Moreover, a total of annual production is about 9,000 tons for various products. Besides. Our products include the standard parts: bowl liner, concave and mantle, jaw plate, shredder hammer, blow bar, impact plate, break plates, VSI parts, PLFC parts, Mill liner for top brands and non-standard crusher parts.

“Better Quality Better Service” is our business principle. Through tens years cooperation with our customers from domestic and abroad. We get good reputation from our customers through our quality castings, and get progress with our customers together in the area of USA, Canada, UK, Australia, Russia, Finland, Poland, Ukraine, Italy, Saudi Arabia, UAE, Oman, Africa, Indonesia, Sri Lanka, India, Malaysia, Mexico, Colombia, Honduras, Peru, Chile, and so on.

You warmly welcome to visit our foundry at your convenience.

What We Supply

Products Range

Bowl Liner, Concave and Mantle, Jaw Plate, Shredder Hammer, Blow Bar, Impact Plate, Break Plates, VSI Parts, PLFC Parts, Mill Liner, Rotor Tip, Cavity Plate, Feed Eye Ring, Feed Tube, Feed Plate, Top Upper Lower Wear Plate, Rotor, Eccentric Shaft, Main Shaft, Shaft Sleeve, Bronze Bushing, Shaft Cap Swing Jaw, Original Shanbao Design Crushers, and so on.

Material We have

Mn13Cr2, Mn18Cr2, Mn22Cr2, Cr30, Cr26, Cr27Mo1, Cr27Mo2, Ceramic Insert, Carbon Steel Insert, Mn13Mo, Mn18Mo

Production Ability

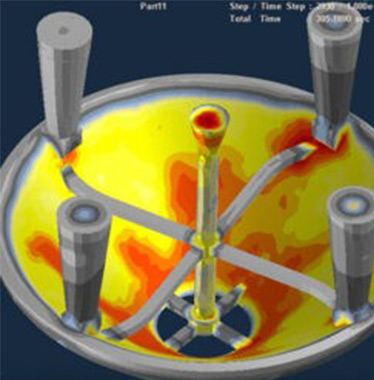

Software

• Solidworks, UG, CAXA, CAD

• CPSS (Casting Process Simulation System)

• PMS, SMS

Middle Frequency Furnance

• 3 tons Medium Frequency Electric Furnace (KGP-2300/0.5S)

• 6 tons Medium Frequency Electric Furnace

• Max weight of castings 6 ton/pcs

• Max diameter of castings 3 meters

Heat Treatment

• 330KW Fiber Cotton heat treatment furnace, working size:2500x1150x800mm, Furnace temperature uniformity <= 10 degree

• 480kw Fiber cotton heat treatment furnace, working size:3000x2500x1500mm, Furnace temperature uniformity <= 8 degree

• 600kw Fiber cotton heat treatment furnace, working size:4000x2000x2000mm, Furnace temperature uniformity <= 8 degree

Machining

• X2016Ax3000 Milling machine

• X3820x3000 Milling machine

• C5225Ex16/10 Double columns vertical lathe

• CA5116Ex10/5 Single column Vertical Lathe

QC Process

• GS1000 Spectrometer, OBLF Elektronik- u.Feinwerk- technik GMBH.

• Metallographic tester.

• Impact testing machine

• Universal tensile testing machine

• N83 Clinometer, E.D.A(SAS Ateliers Laumonier)

• Magnetic particle flaw detector

• Dimension tools

Finishing Improve Equipment

• Q3739 Shot blasting machine, cleanable workpiece size:1700x2200mm / Maximum shot blasting:3x250kw/min

• Water glass (sodium silicate) sand equipment: include sand mixer. MC48 pulsating reverse blowing bag dust collector, HJL-10 sand falling machine, HJP-10 crusher, HJZ-10 pneumatic regeneration machine, FX-10 air separator, DG250 bucket elevator, HJW-15 sand temperature regulator, HJQS650 pneumatic conveying device, HJK-10 electrical control system, and dust removal system.(HJMC-7 high-pressure pulse blowback dust collector and HJM-3 high-pressure pulse blowback dust collector

• Lost foam equipment

• Drying room

• Calibration machine

• Air Hammer

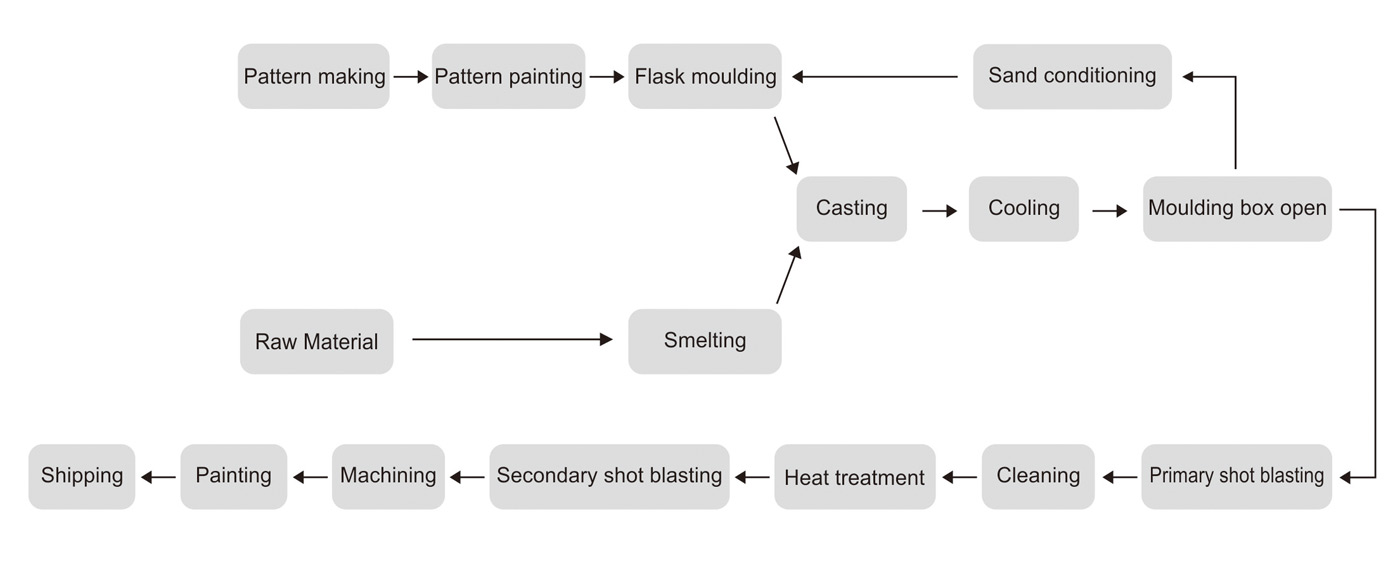

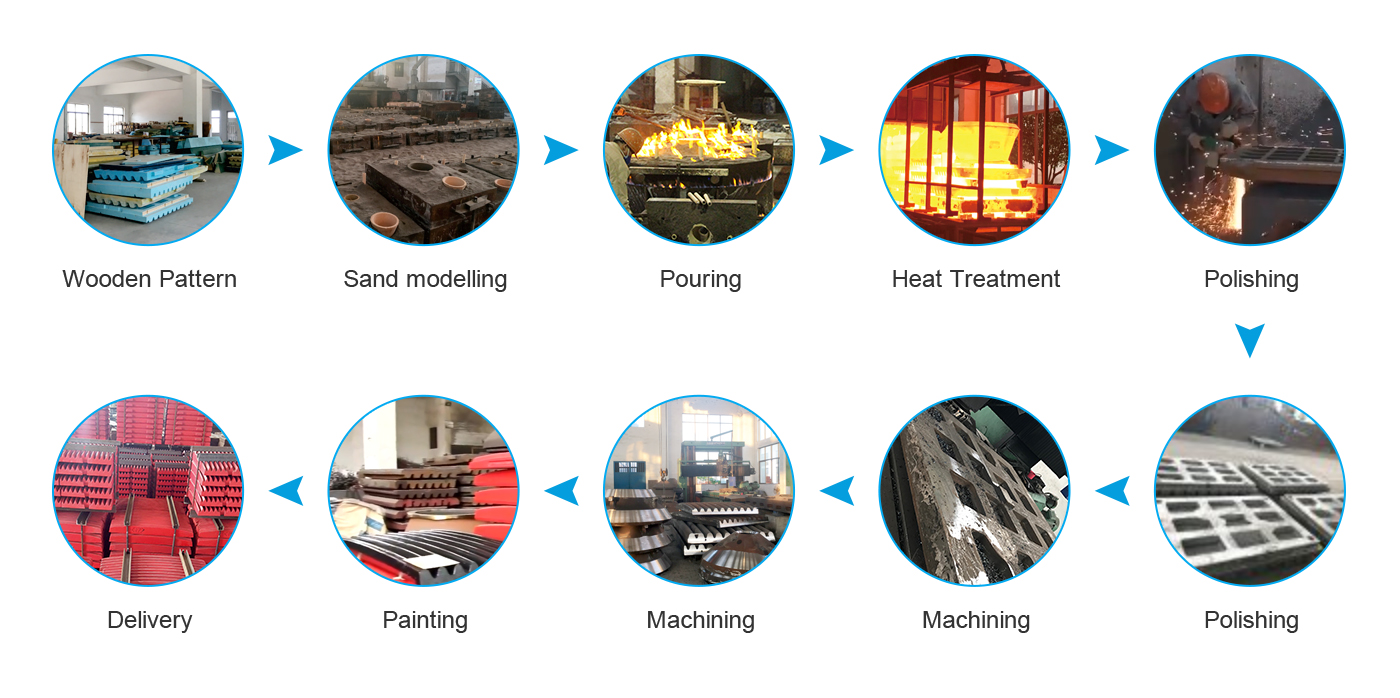

Production Process

Production Flow Chart

Scan the QR code to read on your phone

Products Range

Bowl Liner, Concave and Mantle, Jaw Plate, Shredder Hammer, Blow Bar, Impact Plate, Break Plates, VSI Parts, PLFC Parts, Mill Liner, Rotor Tip, Cavity Plate, Feed Eye Ring, Feed Tube, Feed Plate, Top Upper Lower Wear Plate, Rotor, Eccentric Shaft, Main Shaft, Shaft Sleeve, Bronze Bushing, Shaft Cap Swing Jaw, Original Shanbao Design Crushers, and so on.

Material: Mn13Cr2, Mn18Cr2, Mn22Cr2, Cr30, Cr26, Cr27Mo1, Cr27Mo2, Ceramic Insert, Carbon Steel Insert, Mn13Mo, Mn18Mo…

Contact

DENP Industrial

( Cell Phone / WhatsApp / WeChat )

About us

Founded in 2010, a global manufacturer and supplier of crusher wear parts and spare parts. DENP Foundry takes up 15000 square meters, and produce capacity of around 9000 tons annually, 84 workers and 7 engineers. So if you are looking for crusher wear parts and spare parts.

DENP Industrial deserves your attention!